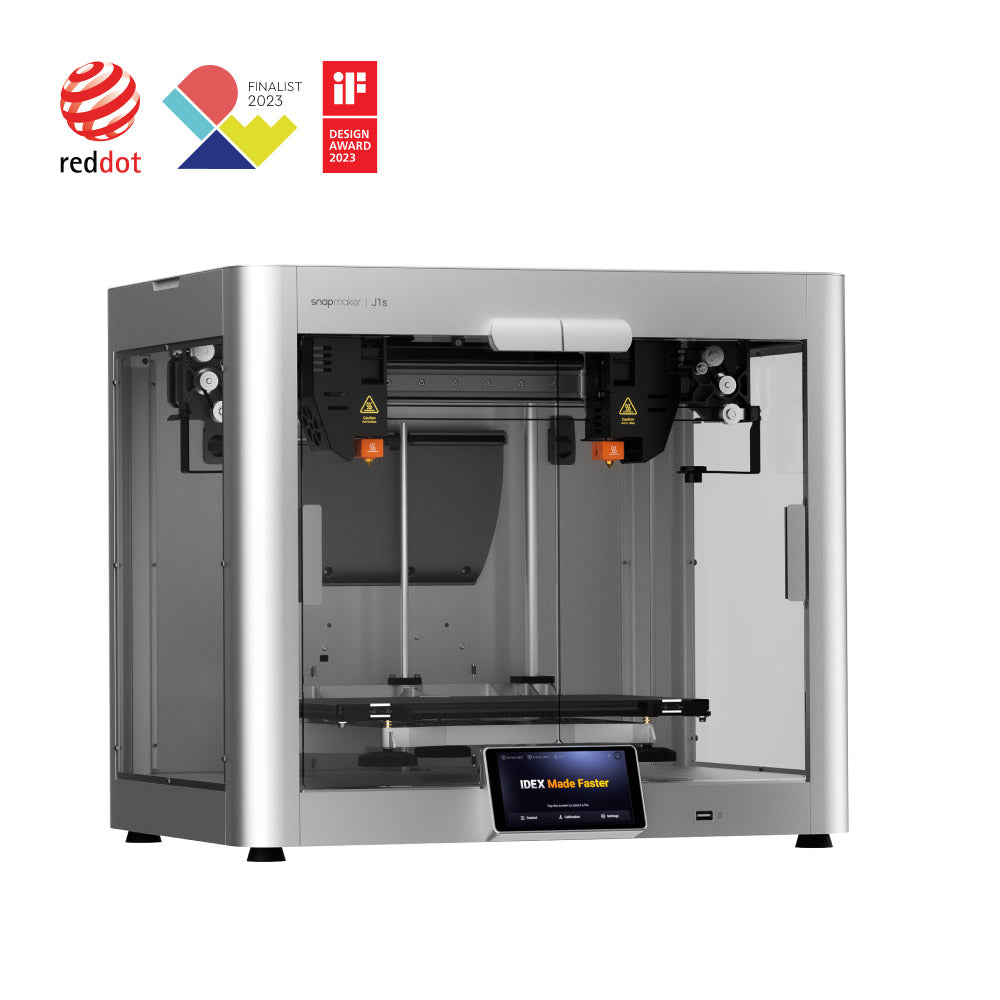

• Fastest IDEX 3D Printer: Max. Speed 350mm/s, Max. Acceleration 10,000mm/s²

• Innovative IDEX Calibration: Hands-free XY Offset Calibration, Tool-free Bed Leveling, Easily-managed Z Offset Calibration

• Easy-to-use: Tailored IDEX 3D Slicer in Luban, 5" Touchscreen

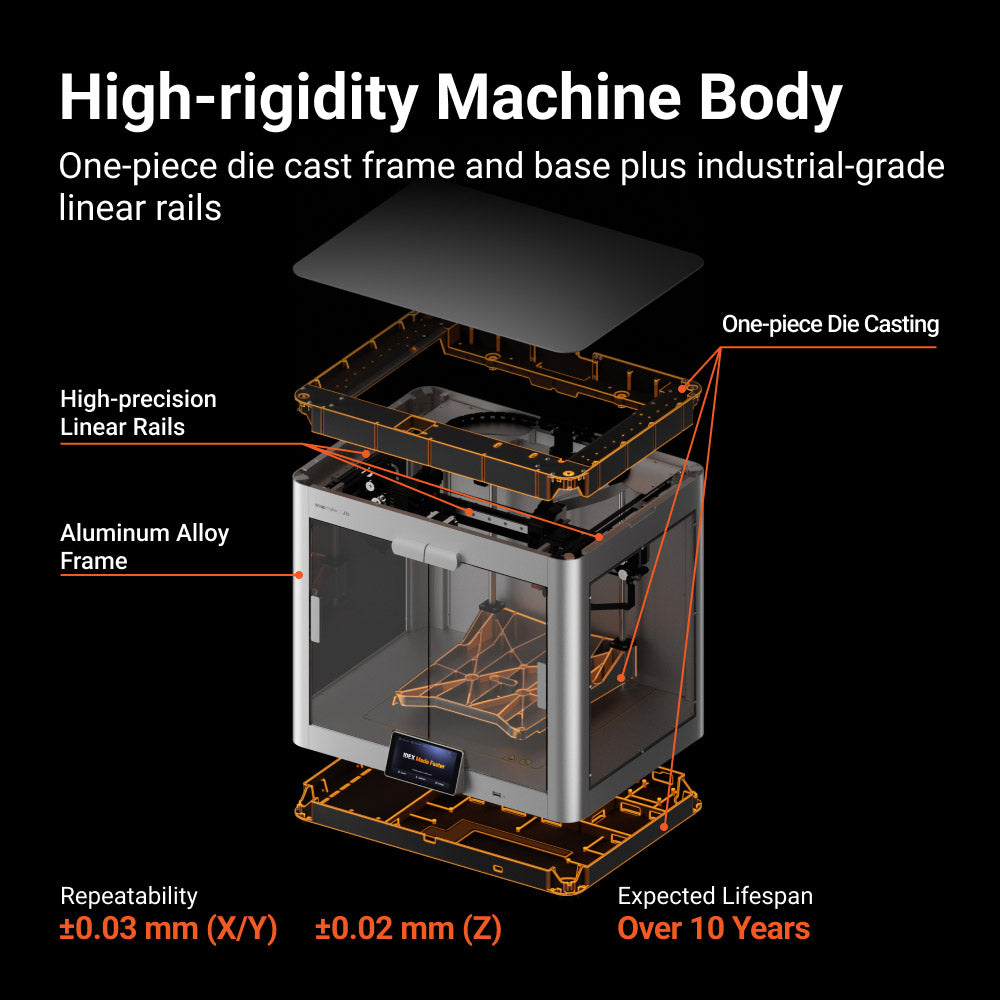

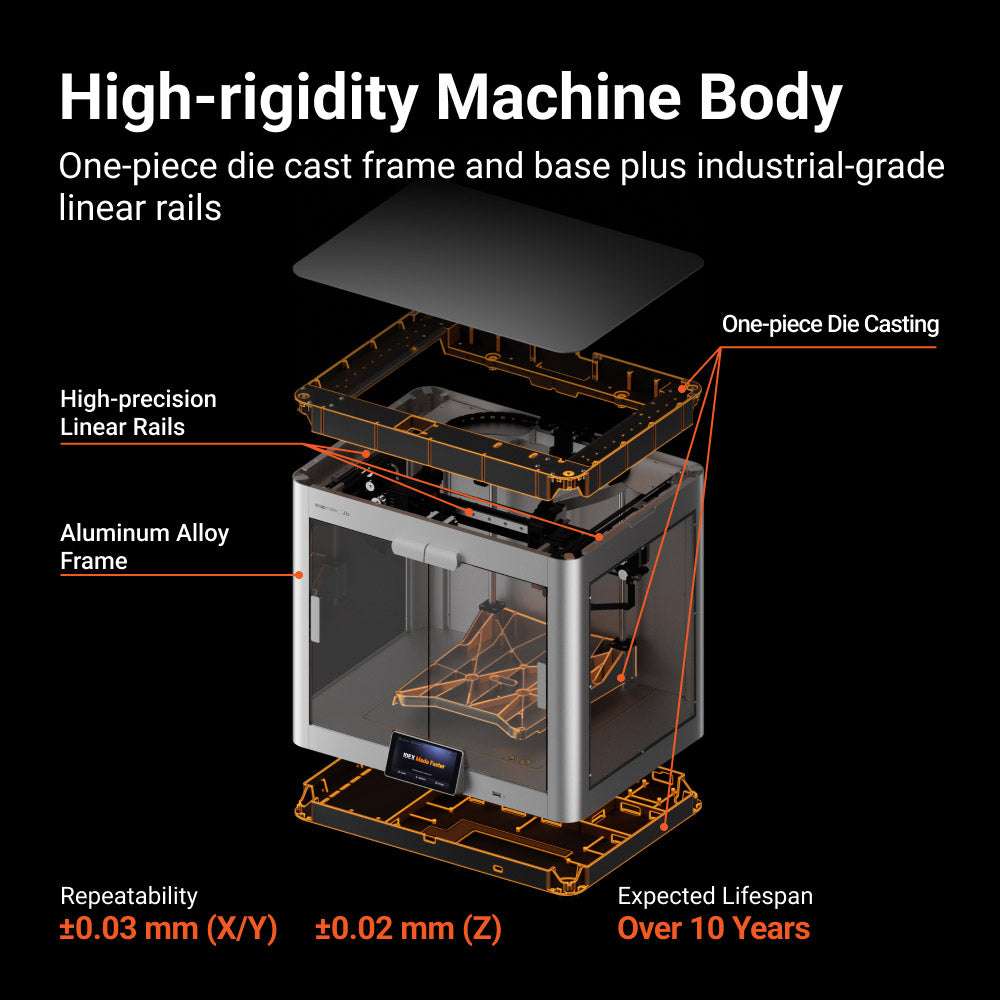

• Well-built Hardware: Linear Rails, One-piece Die Casting, Aluminum Alloy Frame

The main differences between J1 and J1s are as follows

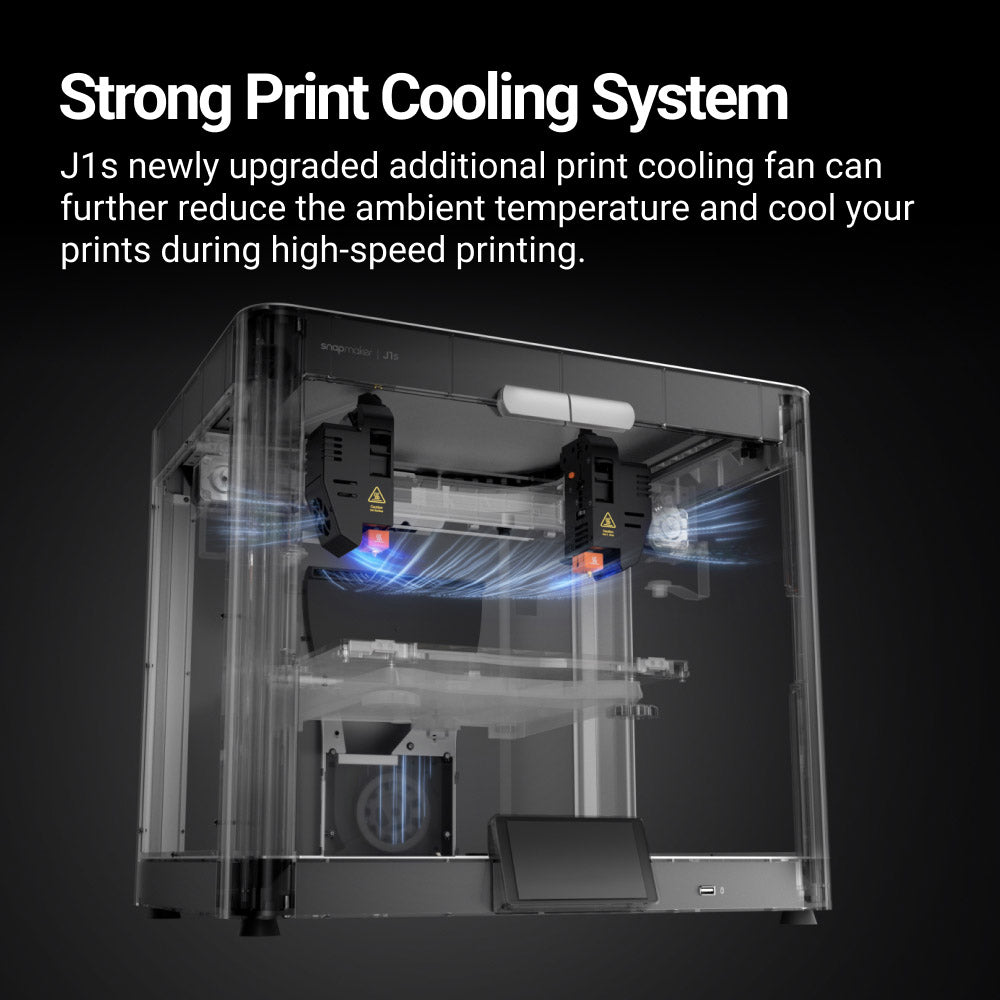

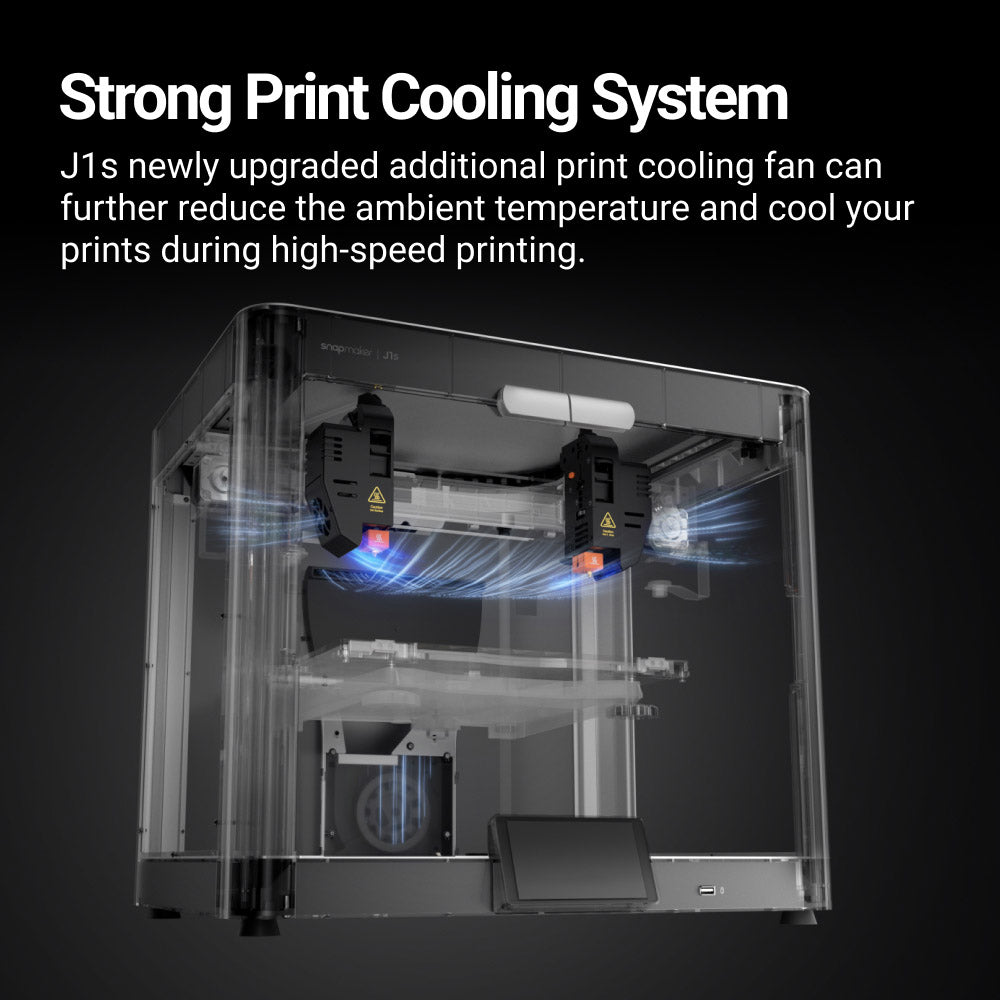

1. The J1s is equipped with the additional Print Cooling Fan. You won't need to remove the top panel to print PLA.

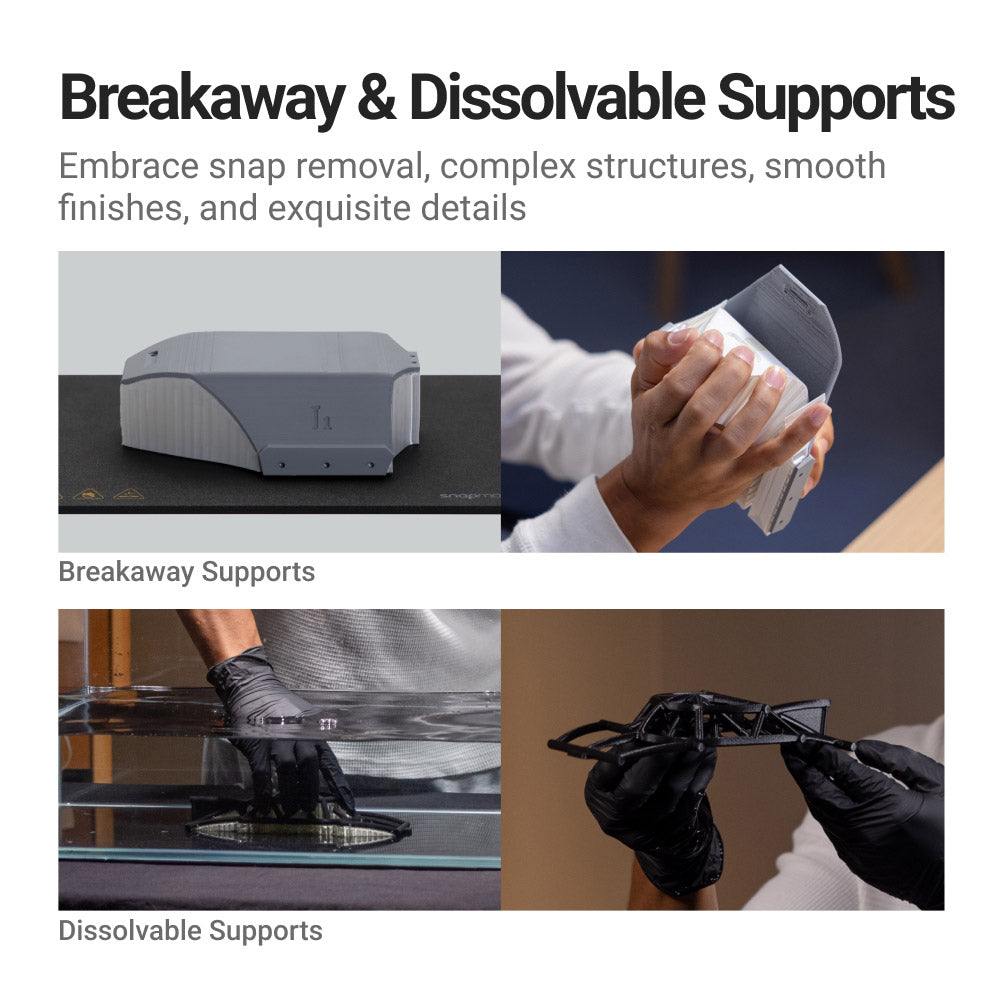

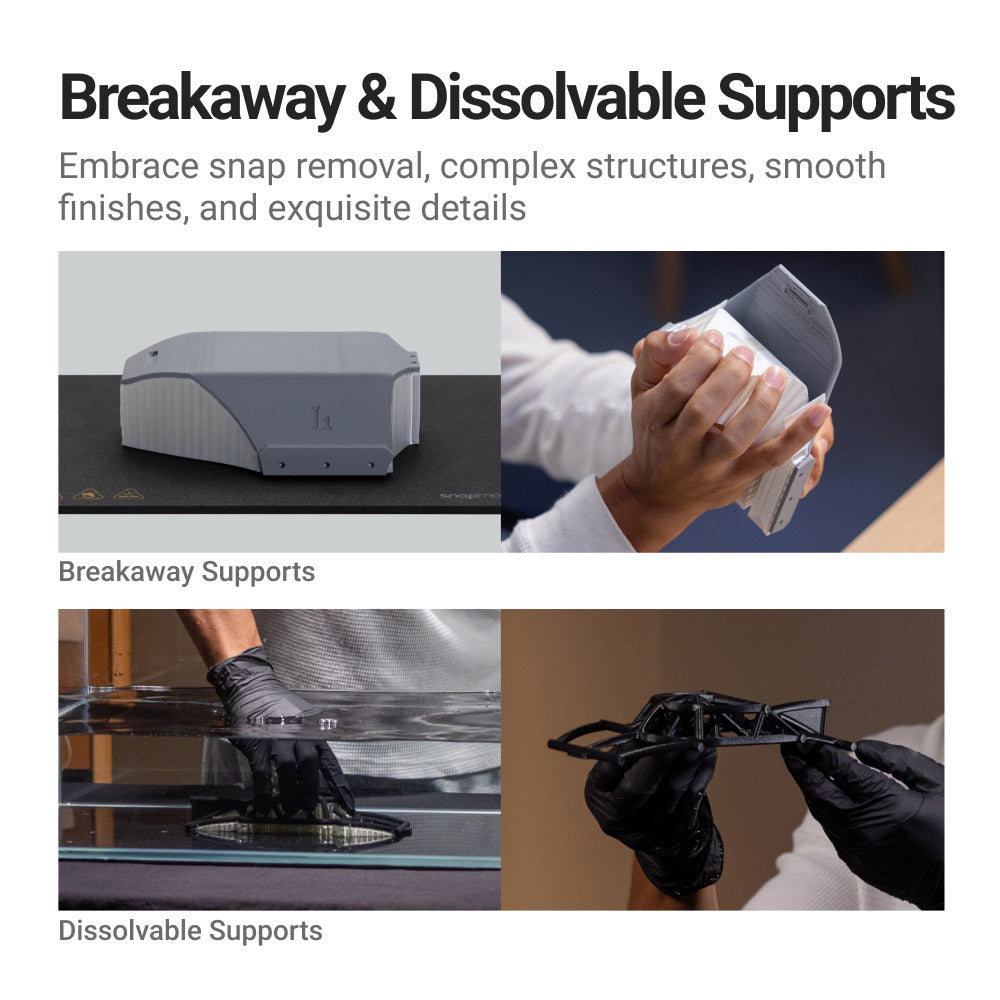

2. In the package of J1s, we replaced the white PLA with Breakaway Support for PLA so that you can try support printing right away.

3. We also pre-installed the doors and side panels for you, making it even easier to start right off.

4. If you plan to buy a J1 model and have the need for extra print cooling, you can choose either a J1 plus an Upgrade Kit or a J1s.

FAQ

Quick Start Guide of the Print Cooling Fan

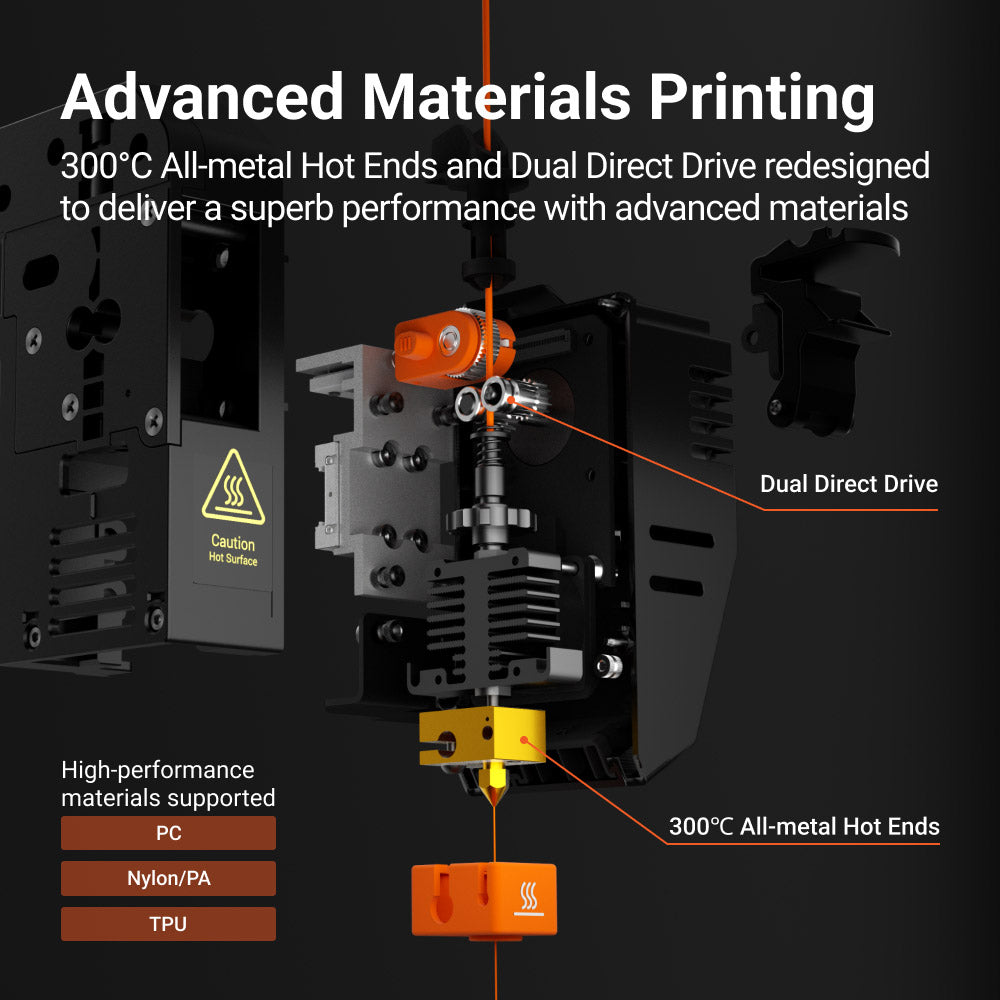

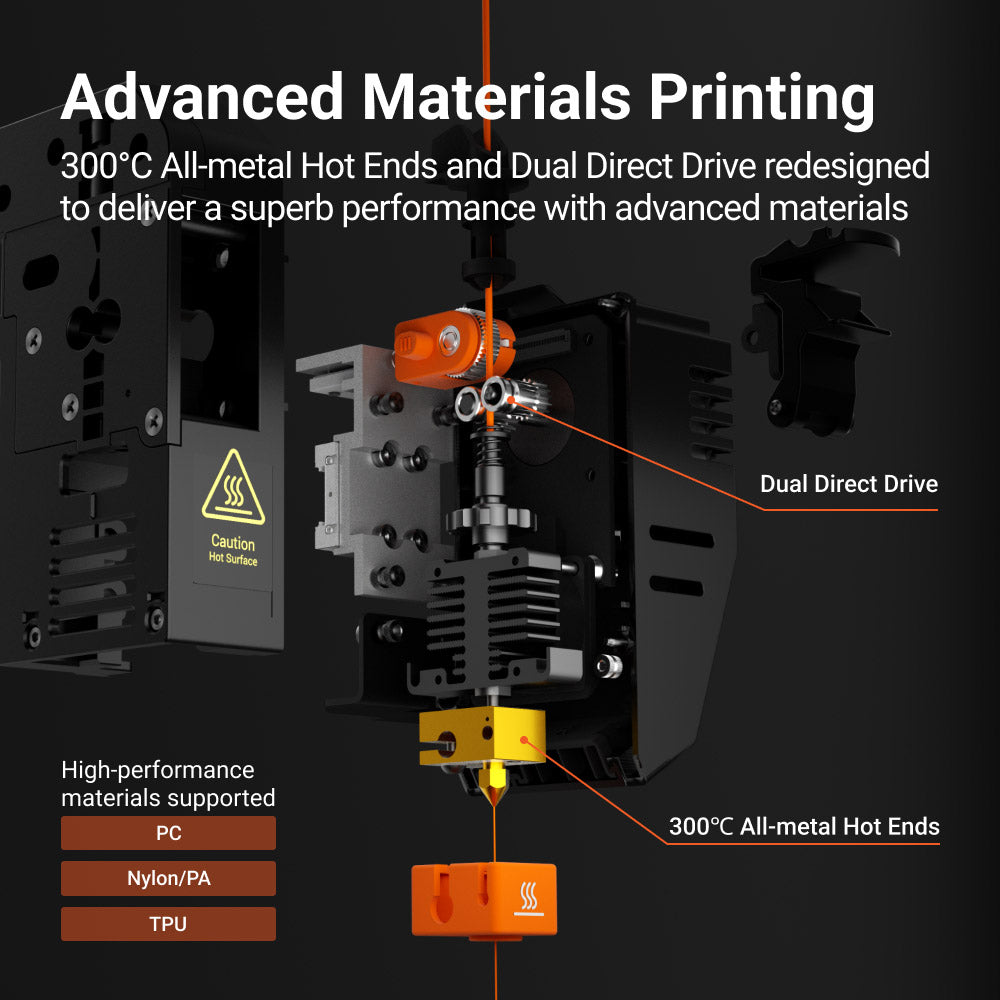

Quick Start Guide of the Hot End