If you have already purchased the Bracing Kit, please click the link here to contact our customer service team for assistance.

Product Overview

• 16x CNC Machining Efficiency: Offers 300% more power and a 50% higher maximum spindle speed than the 50W CNC Module.

• High Machining Quality: Ensured by the strengthened X/Y/Z-axis and 18000 RPM spindle.

• Expanded Material Options for CNC: Precision machining available for hardwood, jade, and other hard materials.

• ER11 Collet: Support over 100 CNC bits.

• Compatibility: Snapmaker 2.0 A250/A250T/A350/A350T/F250/F350, Snapmaker Artisan, Quick Swap Kit

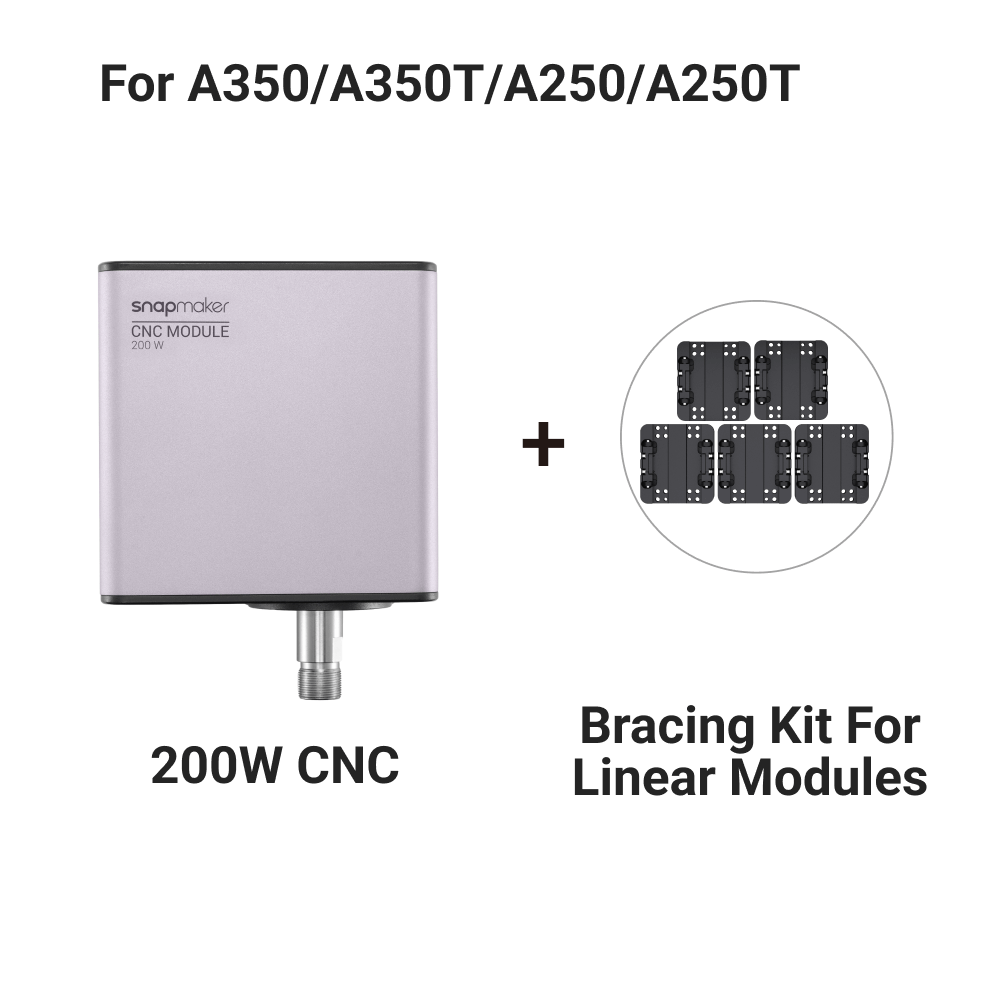

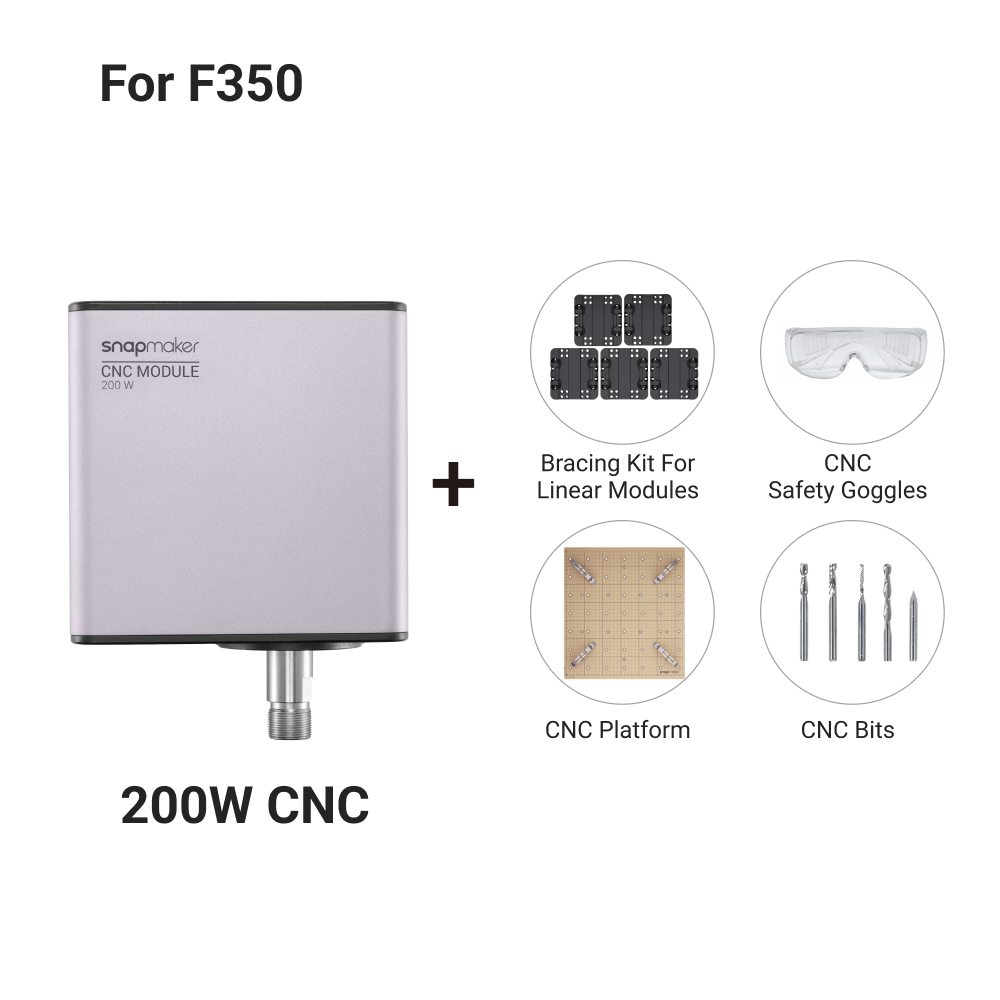

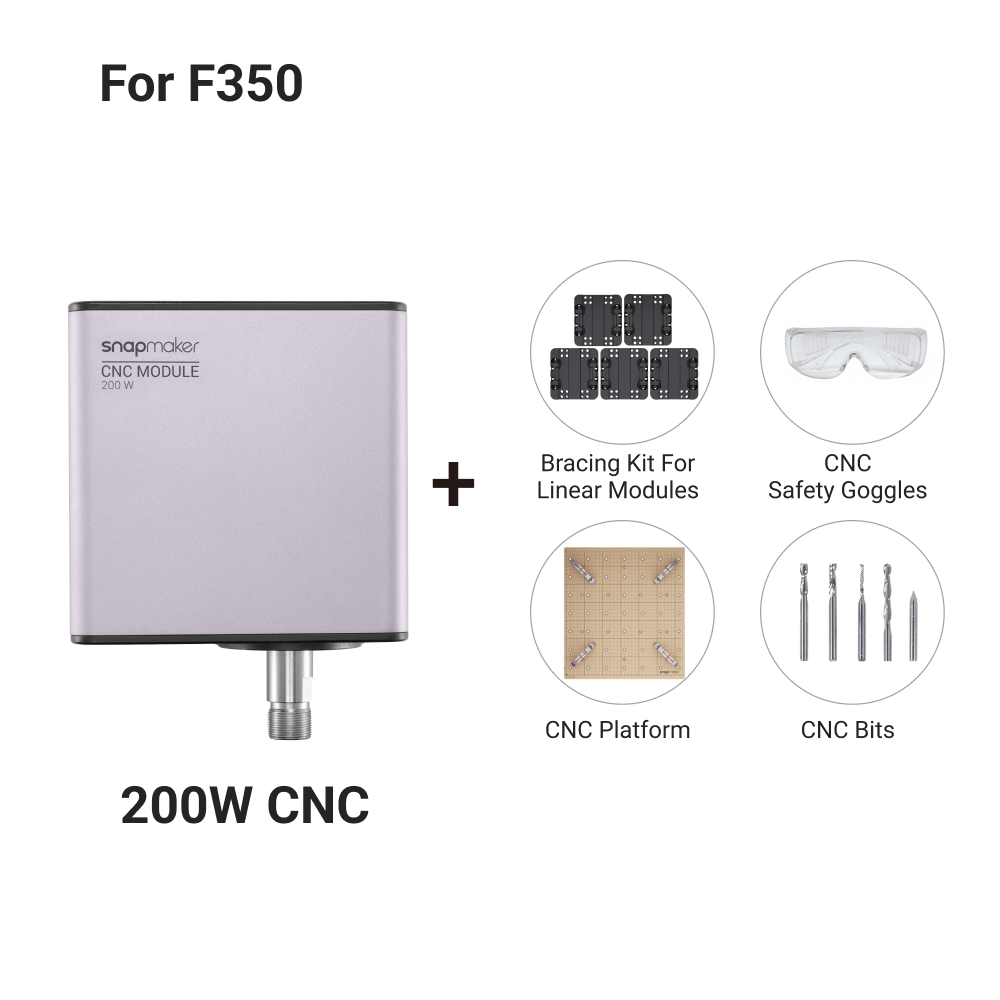

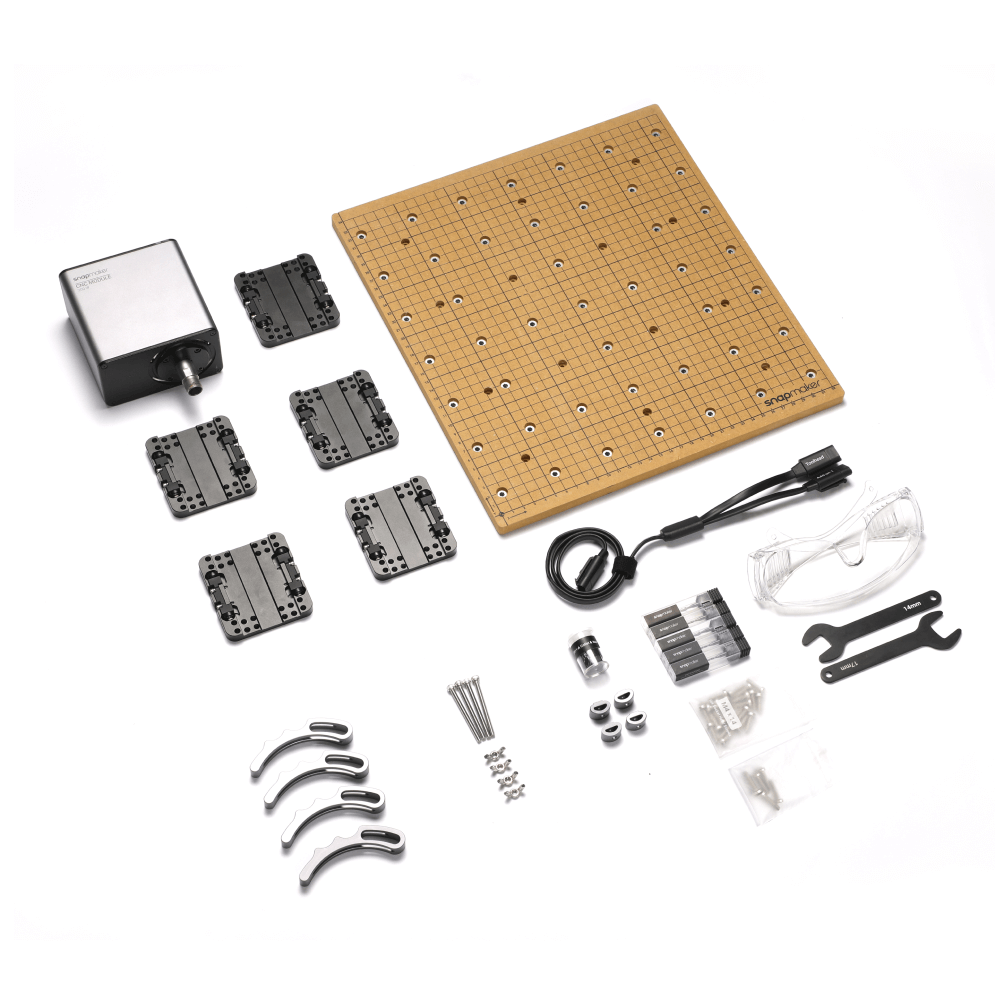

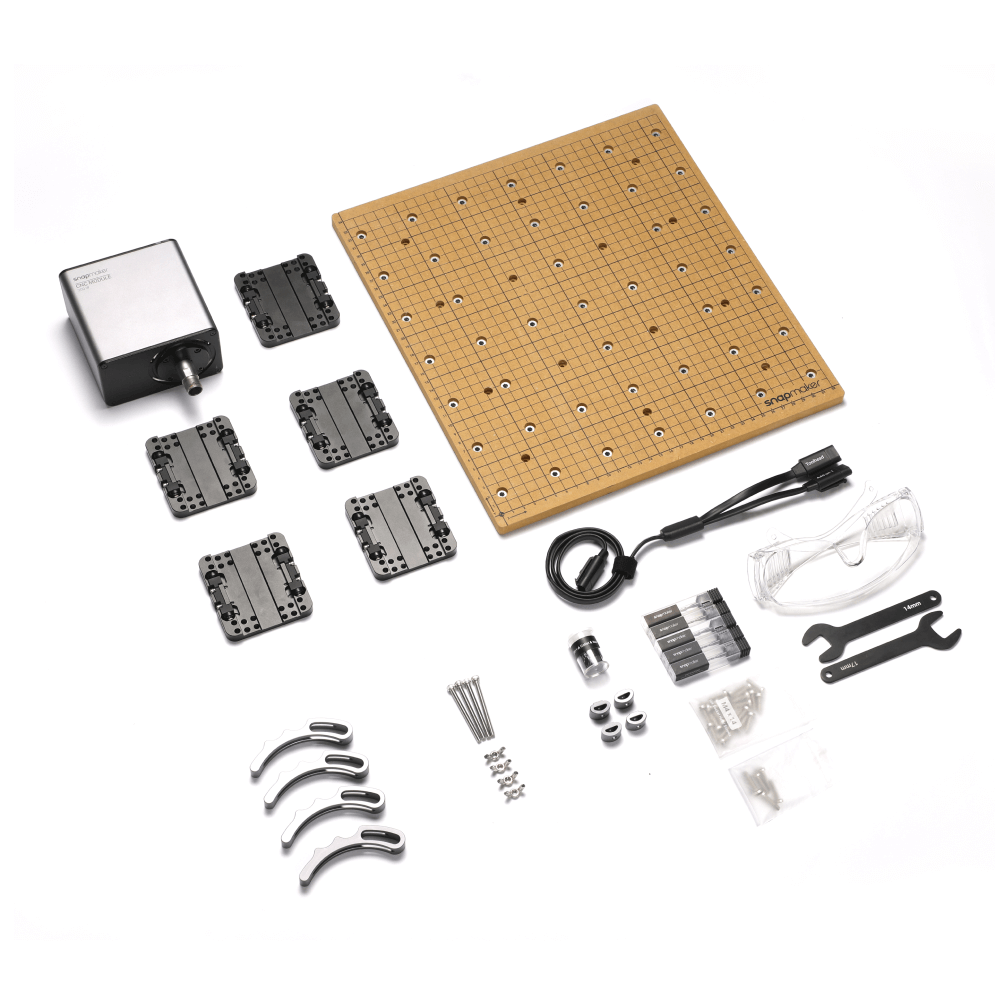

Snapmaker 200W CNC Module Bundle

As low as $14.97/roll (4 rolls) and $13.68/roll (8 rolls)!

SnapSpeed PLA Filament (1kg)

$17.49 $24.99

Matte PLA Filament (1kg)

$16.09 $22.99

Basic PLA Filament (1kg)

$20.90 $24.99

PETG Filament (1kg)

$20.90 $24.99

ABS Filament (1kg)

$20.90 $24.99

Couldn't load pickup availability

Payment methods

16x CNC machining efficiency.

The 200W CNC Bundle offers 300% more power and a 50% higher spindle speed than the 50W CNC Module (without Bracing Kit), increasing beech machining efficiency by 16 times.

High machining quality.

The Linear Modules for Snapmaker 2.0, equipped with the Bracing Kit for added rigidity, along with the 18000 RPM spindle, empower the 200W CNC module to smoothly carve or cut various materials with high machining quality.

A wider variety of materials for CNC.

You have the option to choose from a wider variety of materials for CNC. The 200W CNC Module is capable of precision machining on hardwood (such as beech and walnut), jade, and other hard materials.

4-axis CNC machining.

The Snapmaker Rotary Module (Harmonic Drive Version) adds a 4th axis to your Snapmaker, making it an extremely mighty desktop CNC machining powerhouse.

ER11 collet.

The standard ER11 collet ensures better concentricity, enabling a more stable CNC carving speed and larger step-down. Additionally, the collet nut supports over 100 CNC bits with shank diameters ranging from 1mm to 7mm (the provided collet is for 3.175mm CNC bits only).

Specifications

Dimensions (W × D × H)

105mm × 65mm × 137.5mm

Weight

0.19 kg

Power

200W

Max. Spindle Speed

18,000 RPM

Supported Materials (Ideal)

Hardwood (Beech, Walnut), Softwood, HDF, MDF, Plywood, Jade, Carbon Fiber, Acrylic, Epoxy Tooling Board, PCB

Supported Materials (Capable)

Aluminum (1000-6000 Series), Brass, Red Copper

Supported Formats

stl, svg, png, jpg, jpeg, bmp, dxf

Work Area (200W CNC)

A250/A250T/F250: 230mm × 225mm

A350/A350T/F350: 320mm × 325mm

Artisan: 400mm × 400mm

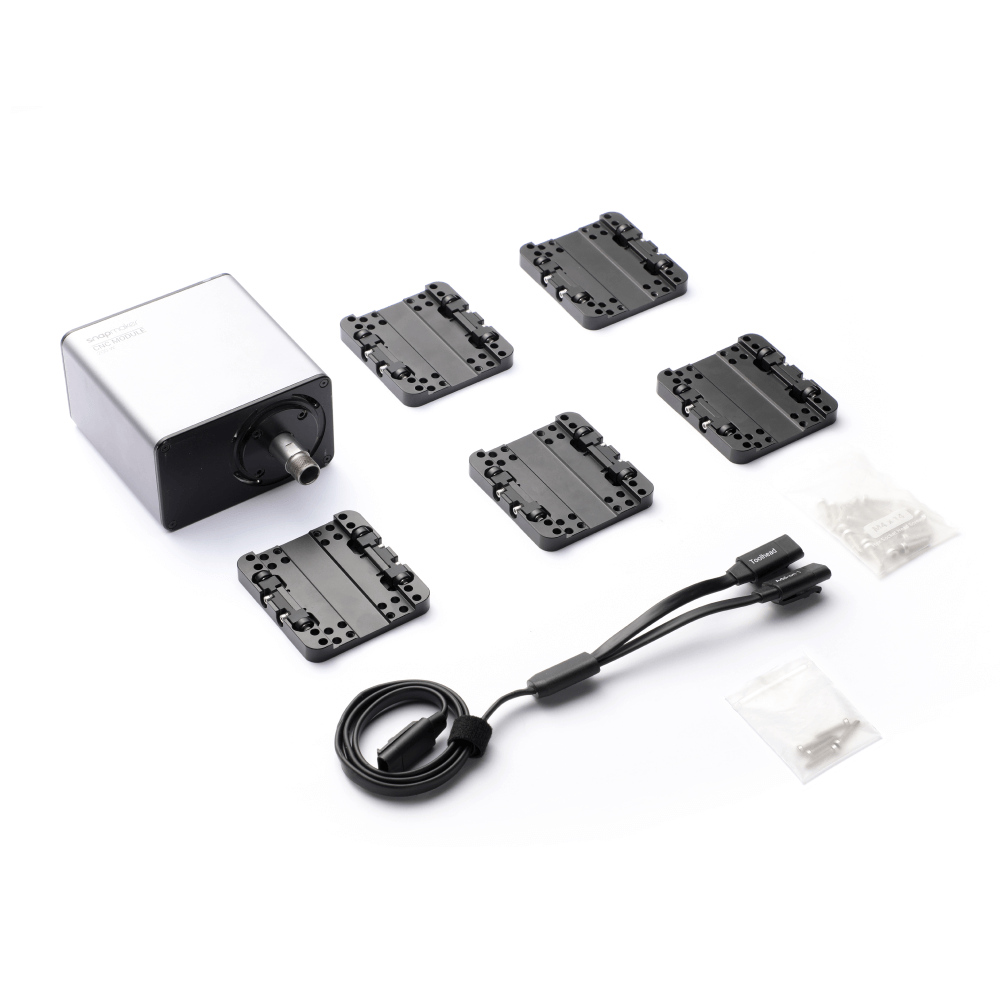

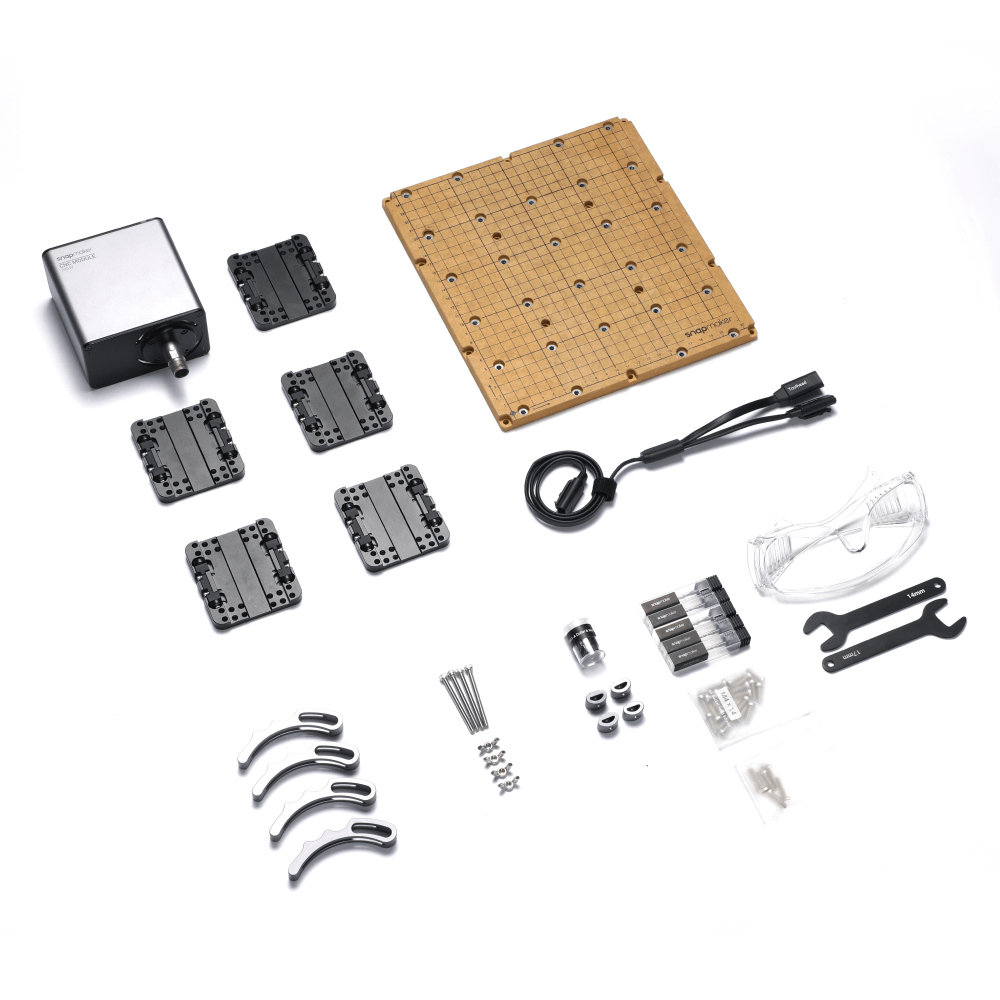

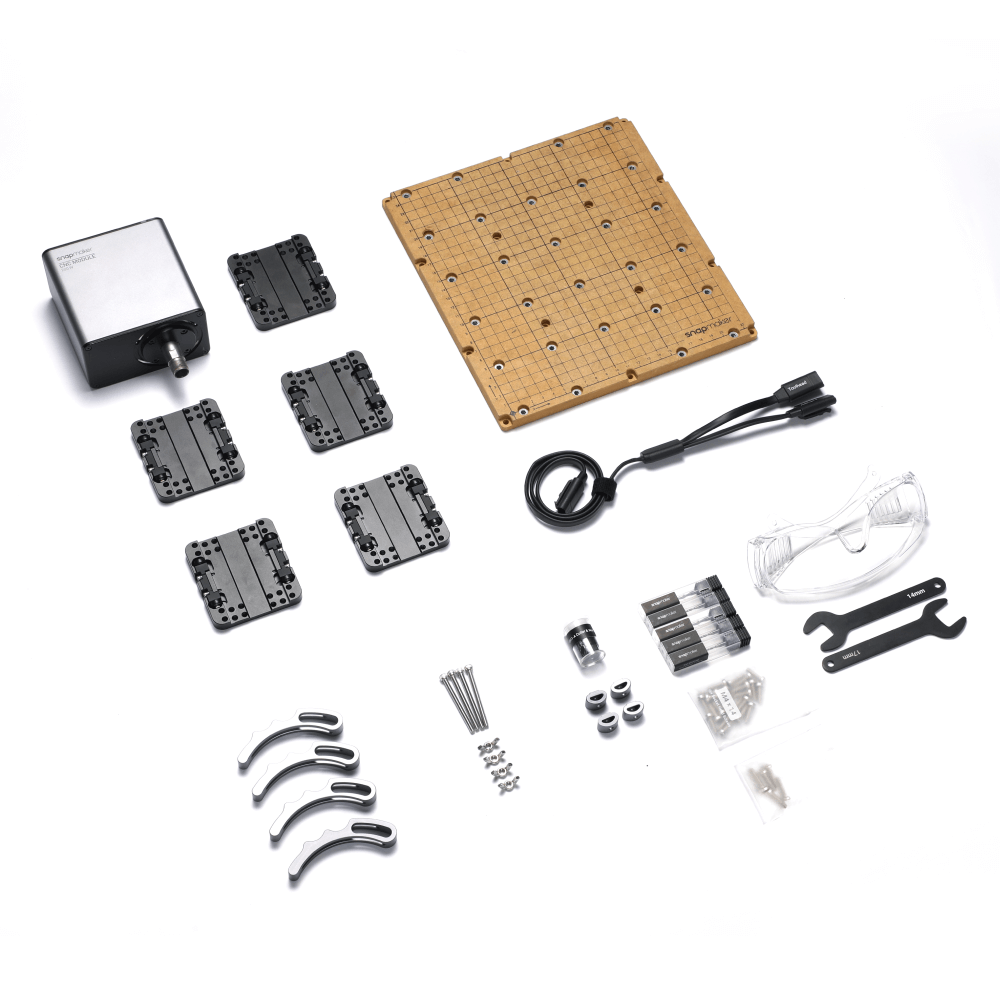

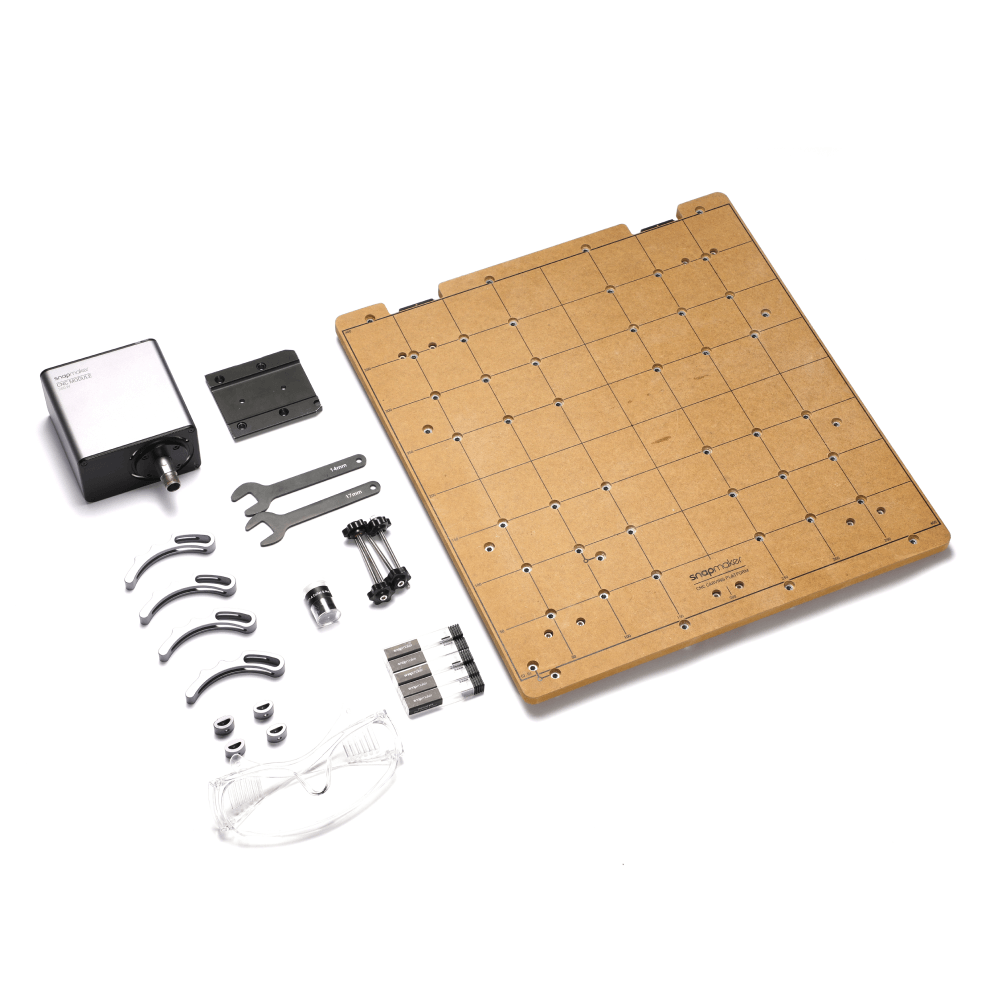

In the Box

200W CNC Module Bundle for A250/A250T/A350/A350T

200W CNC Module Bundle for F350

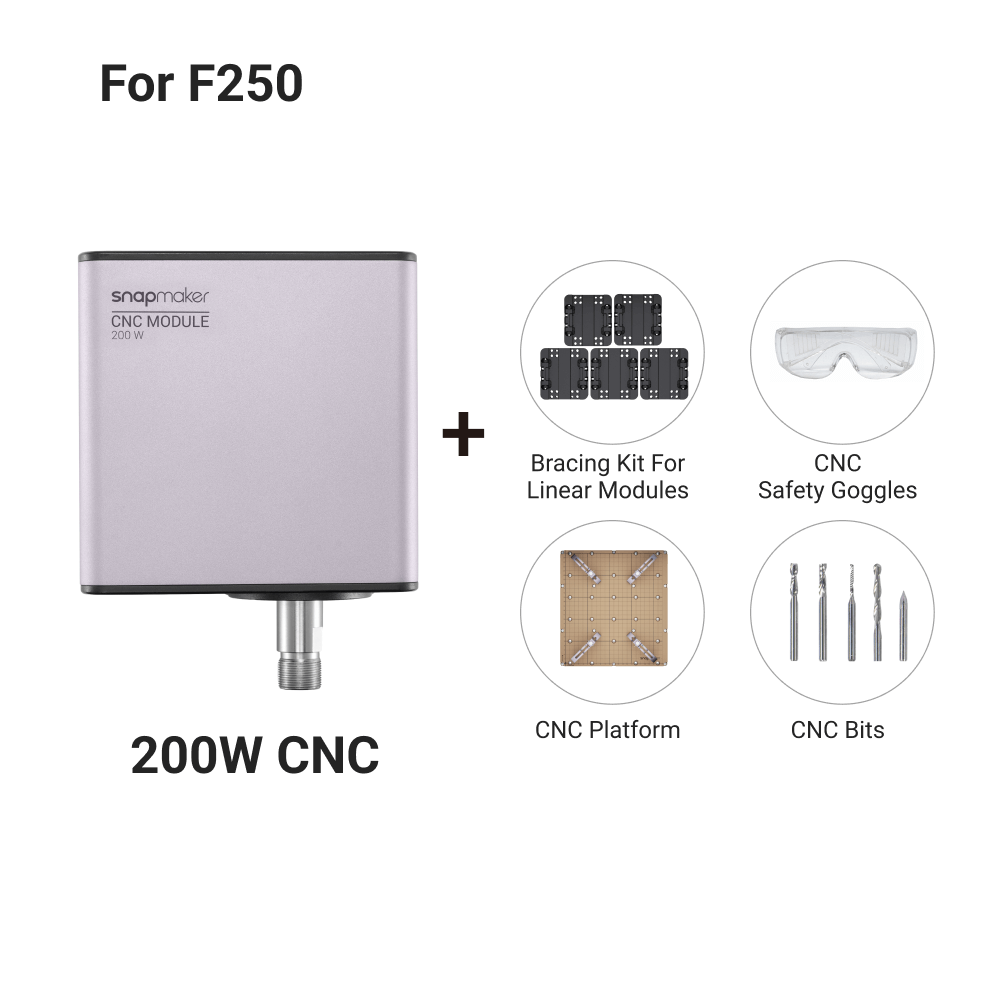

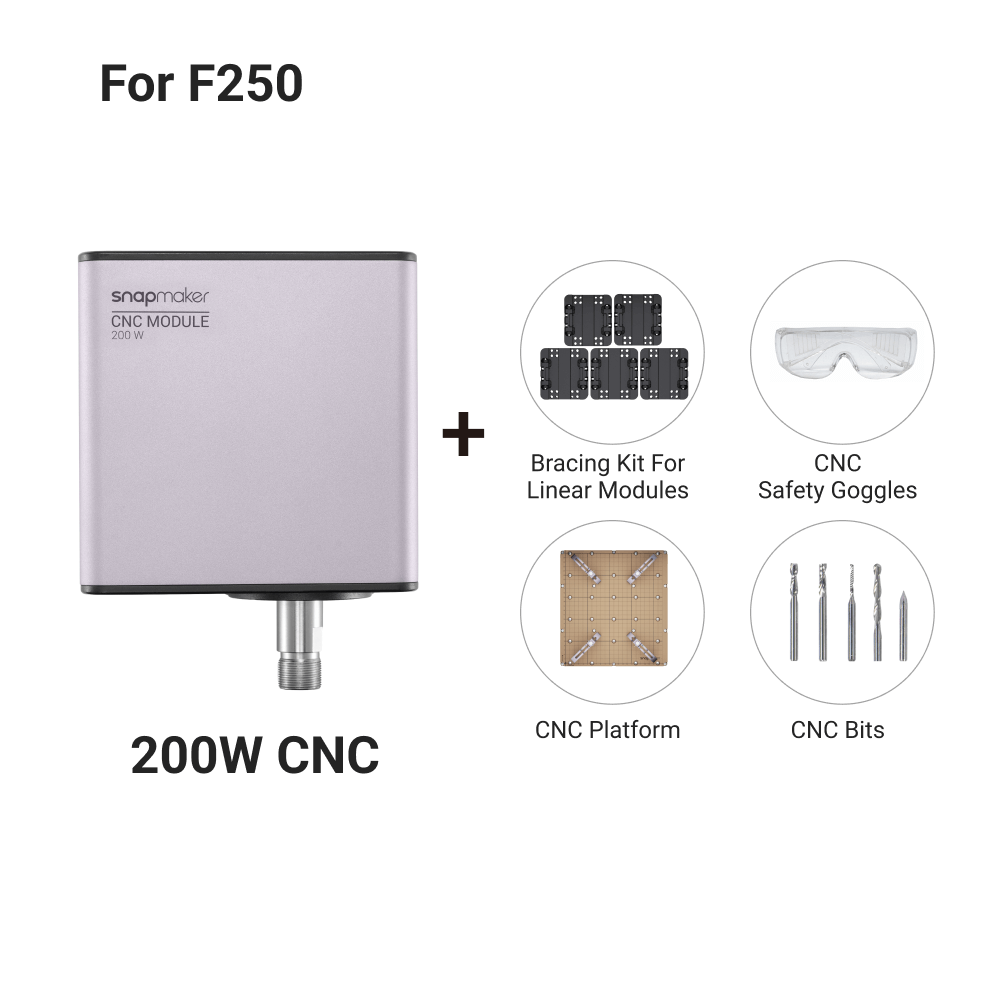

200W CNC Module Bundle for F250

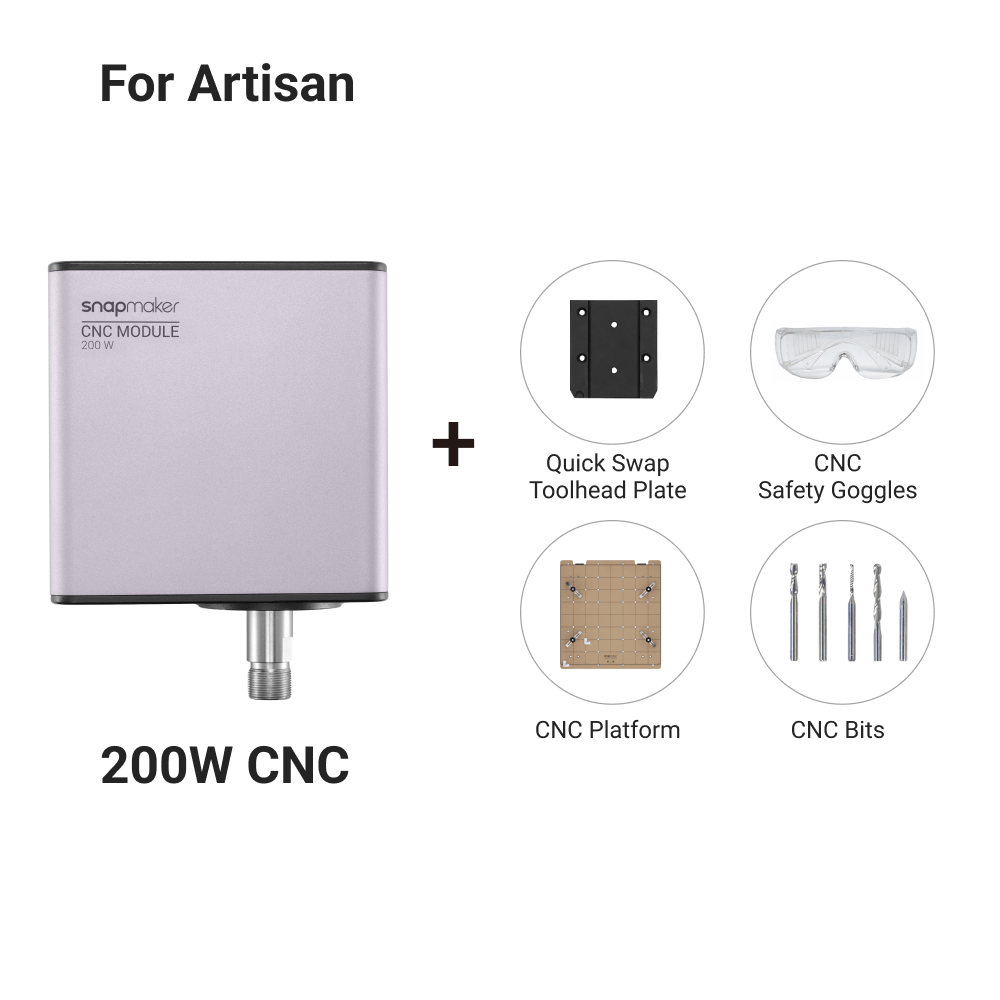

200W CNC Module Bundle for Artisan

Notes:

[1] The test was performed with 3.175mm Flat End Mill (Double Flute).

Frequently Asked Questions

1. What type of file formats are supported for CNC machining?

The Snapmaker 200W CNC Module supports STL, SVG, PNG, JPG, JPEG, BMP, and DXF file formats.

2. How does a bracing kit improve 200W CNC machining performance?

A bracing kit enhances the structural stability of CNC router by reducing vibrations and ensuring more accurate operations. This stabilization not only improves the precision of machining tasks but also diminishes stress and wear on the machine's components, potentially extending the module's lifespan.

3. What is the maximum cutting depth of 200W CNC module?

The suggested maximum cutting depth is 15 mm. This depth allows for a range of machining tasks but varies based on the specific bit being used for the CNC machining operation.

4. Why is the 200W CNC module not compatible with the A150 Printer?

The A150 printer is designed with a single-axis cantilever structure, which means its support for the single Z-axis is not robust enough to handle the demands of a 200W CNC module.

5. Are the cutter head diameters of the 50W CNC module and the 200W CNC module compatible?

Yes, the cutter head diameters of the 50W CNC Module and the 200W CNC Module are compatible.

6. What safety precautions should be taken while using CNC module?

• Use Enclosure: Operate the CNC Module within an enclosure to contain debris and reduce noise.

• Wear Safety Goggles: All users and bystanders must wear CNC safety goggles during operation to protect against flying debris.

• Secure Material: Before starting, ensure the material is securely clamped to prevent movement.

• Avoid Contact: Never attempt to hold the workpiece with your hands during the CNC process. Do not touch the bit or collet immediately after use; they can be very hot.

• Respond to Jams: If there's a jam, turn off the machine immediately, wait for all moving parts to stop, then safely clear the jam.

• Ventilation: Use air purifying devices or operate in a well-ventilated area to minimize exposure to toxic substances released during machining.

16x CNC machining efficiency.

The 200W CNC Bundle offers 300% more power and a 50% higher spindle speed than the 50W CNC Module (without Bracing Kit), increasing beech machining efficiency by 16 times.

High machining quality.

The Linear Modules for Snapmaker 2.0, equipped with the Bracing Kit for added rigidity, along with the 18000 RPM spindle, empower the 200W CNC module to smoothly carve or cut various materials with high machining quality.

A wider variety of

materials for CNC.

You have the option to choose from a wider variety of materials for CNC. The 200W CNC Module is capable of precision machining on hardwood (such as beech and walnut), jade, and other hard materials.

4-axis CNC machining.

The Snapmaker Rotary Module (Harmonic Drive Version) adds a 4th axis to your Snapmaker, making it an extremely mighty desktop CNC machining powerhouse.

ER11 collet.

The standard ER11 collet ensures better concentricity, enabling a more stable CNC carving speed and larger step-down. Additionally, the collet nut supports over 100 CNC bits with shank diameters ranging from 1mm to 7mm (the provided collet is for 3.175mm CNC bits only).

Specifications

Dimensions (W × D × H)

105mm × 65mm × 137.5mm

Weight

0.19 kg

Power

200W

Max. Spindle Speed

18,000 RPM

Supported Materials (Ideal)

Hardwood (Beech, Walnut), Softwood, HDF, MDF, Plywood, Jade, Carbon Fiber, Acrylic, Epoxy Tooling Board, PCB

Supported Materials (Capable)

Aluminum (1000-6000 Series), Brass, Red Copper

Supported Formats

stl, svg, png, jpg, jpeg, bmp, dxf

Work Area (200W CNC)

A250/A250T/F250: 230mm × 225mm

A350/A350T/F350: 320mm × 325mm

Artisan: 400mm × 400mm

In the Box

200W CNC Module Bundle for

A250/A250T/A350/A350T

200W CNC Module Bundle for F350

200W CNC Module Bundle for F250

200W CNC Module Bundle for Artisan

[1] The test was performed with 3.175mm Flat End Mill (Double Flute)

Frequently Asked Questions

1. What type of file formats are supported for CNC machining?

The Snapmaker 200W CNC Module supports STL, SVG, PNG, JPG, JPEG, BMP, and DXF file formats.

2. How does a bracing kit improve 200W CNC machining performance?

A bracing kit enhances the structural stability of CNC router by reducing vibrations and ensuring more accurate operations. This stabilization not only improves the precision of machining tasks but also diminishes stress and wear on the machine's components, potentially extending the module's lifespan.

3. What is the maximum cutting depth of 200W CNC module?

The suggested maximum cutting depth is 15 mm. This depth allows for a range of machining tasks but varies based on the specific bit being used for the CNC machining operation.

4. Why is the 200W CNC module not compatible with the A150 Printer?

The A150 printer is designed with a single-axis cantilever structure, which means its support for the single Z-axis is not robust enough to handle the demands of a 200W CNC module.

5. Are the cutter head diameters of the 50W CNC module and the 200W CNC module compatible?

Yes, the cutter head diameters of the 50W CNC Module and the 200W CNC Module are compatible.

6. What safety precautions should be taken while using CNC module?

• Use Enclosure: Operate the CNC Module within an enclosure to contain debris and reduce noise.

• Wear Safety Goggles: All users and bystanders must wear CNC safety goggles during operation to protect against flying debris.

• Secure Material: Before starting, ensure the material is securely clamped to prevent movement.

• Avoid Contact: Never attempt to hold the workpiece with your hands during the CNC process. Do not touch the bit or collet immediately after use; they can be very hot.

• Respond to Jams: If there's a jam, turn off the machine immediately, wait for all moving parts to stop, then safely clear the jam.

• Ventilation: Use air purifying devices or operate in a well-ventilated area to minimize exposure to toxic substances released during machining.