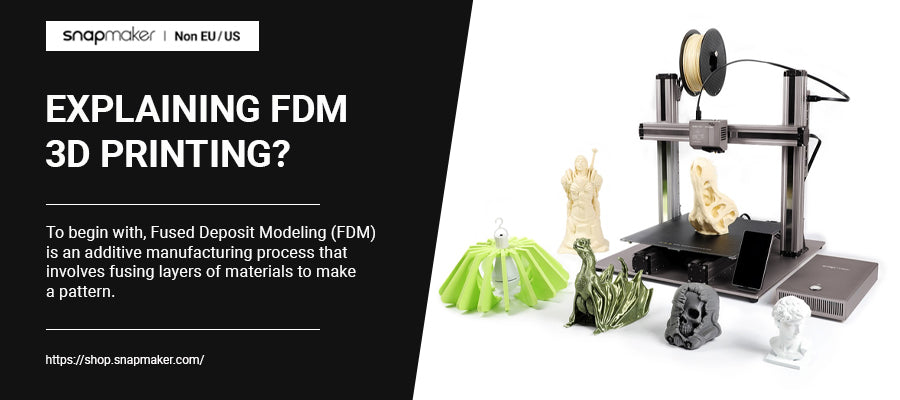

This article will explain what exactly FDM 3D printing is, how it works, and the pros of FDM. To begin with, Fused Deposit Modeling (FDM) is an additive manufacturing process that involves fusing layers of materials to make a pattern. An FDM 3D printer takes plastic filaments and crushes them through hot temperatures to melt in layman's terms. The melted materials are then deposited layer by layer on the print bed. FDM is always the first process that comes to mind when it comes to 3D printing.

How Does FDM 3D Printing Work?

In FDM, digital design files are uploaded into the printer, translating the files into physical dimensions. Some of the materials used for FDM 3D printing include polymers such as PLA, PETG, and ABS. If you are looking for a shop to buy the best PLA filament, then Snapmaker is recommended. There, you will find PLA filament in one kilogram and five hundred grams.

To start the process of FDM, you first load the machine with a thermoplastic filament. The nozzle will heat up, and once it reaches the correct temperatures, the machine will feed the filament through the extrusion head and nozzle. Each material has its nozzle; for instance, in FDM 3D printing, where hard materials are used, you will need a steel nozzle that can resist the abrasion of the hard filament.

Once the melted material is deposited, it cools off and solidifies. Fans can be added to the extrusion, making the process fast. Once the printer finishes a layer, the built layer descends, and the printer begins to work on another layer. However, in some machines, the extrusion head moves up. This process continues until the whole exercise of 3D printing is complete.

Advantages

One of the significant advantages of FDM is scalability, as you can scale it to any size. If you make the gantry rails longer, the built-in area can also be increased. Hence you will be able to make large objects. Another benefit of FDM is that you can use various materials in the same machine. You can use different materials on an FDM printer with very few modifications and upgrades. This is not the case in other styles of 3D printing where materials can only be resin or fine powder.

Conclusion

FDM is the widely used 3D printing technology to build strong, durable, and dimensionally stable parts of models. The development of FDM technology has been on an upward trend, and it will continue developing into a real leader when it comes to the manufacturing process. Do you want to jump on the 3D printing train? Then visit the Snapmaker online shop for the best filament materials for FDM 3D printing.